Our Process

Home / Our Process

Printing Process

01

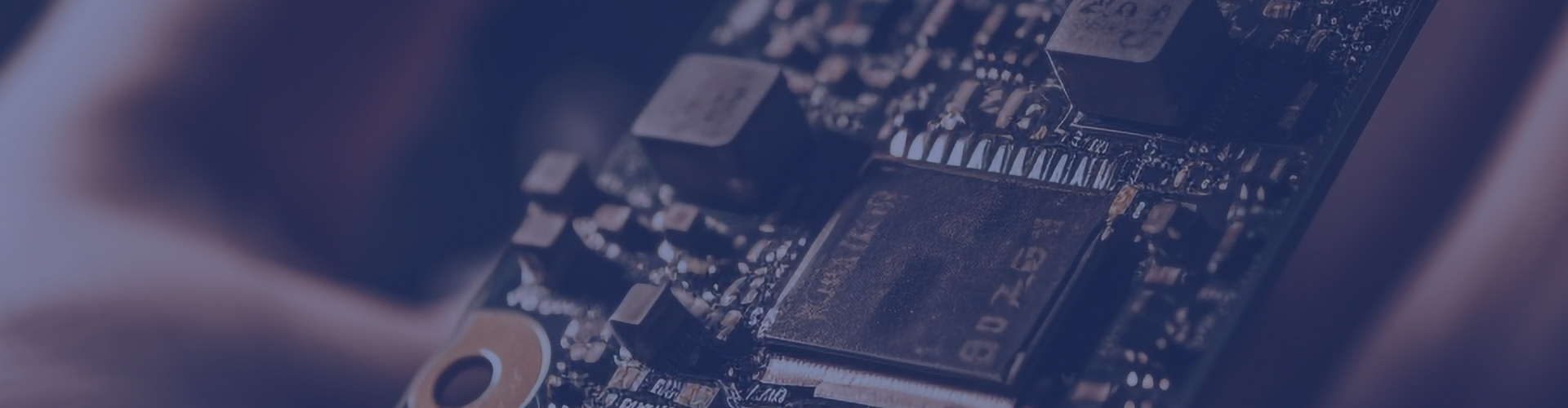

The Printing cycle begin by flooding the etched area of the printing plate with ink. Printing machines use either an open inkwell or a closed ink cup, which will prevent solvents from evaporating in the inkwell. The ink must have a low viscosity allowing it to flow out evenly over the surface of the plate and into the etched image area.

02

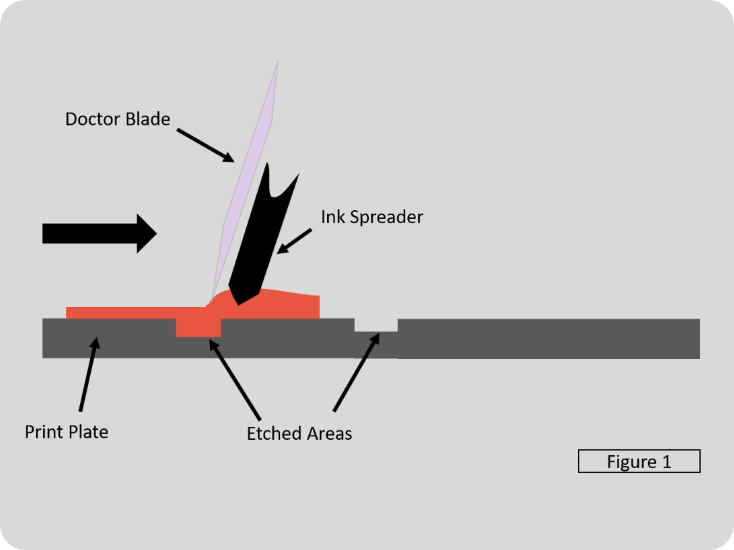

The top surface of the plate is cleaned using doctor blade, leaving the printing ink in the etched area containing the image.

03

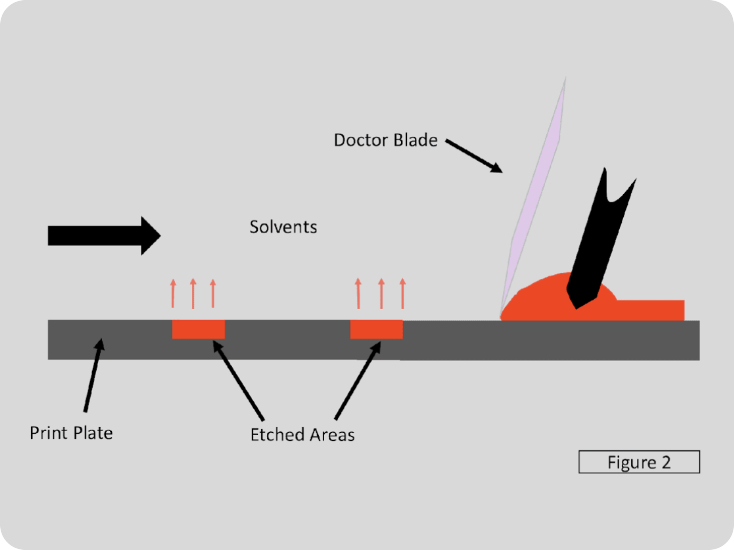

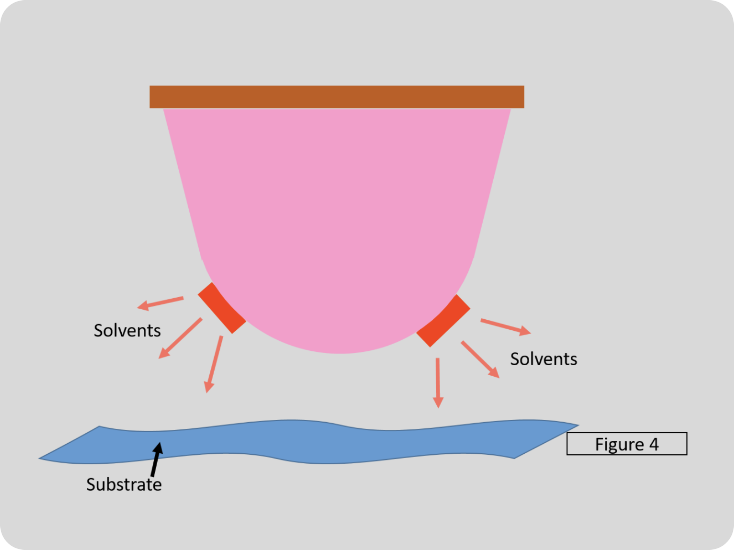

The transfer pad is compressed onto the surface of the plate in an even, rolling action, pushing air out of the way as it compresses. As the solvent evaporate from the surface of the ink, the increased tackiness of the exposed ink surface enables it to stick to the pad and be transferred to the pad from the etched surface of the printing plate.

04

After the ink is lifted from the plate the surface of the ink film on the pad starts to dry, making that surface become tackier.

Why Failure Of Marking

Ink

- Use of an inapproprite Ink

- Improperly formulated Ink

- Improper film thickness

- Inadequate cure

- Substrate surface contamination

Pad

- Package design

- Hardness

- Surface contamination

Plate

- Depth of etching

Trust Us, We Making It Mark!

Our deep knowledge of different substrates enables us to suggest and test. Listen to our printing experts and to discuss ink adhesion methods in printing process. We offer printing services that include consulting and assistance for choosing the correct technology for setting up your operation. Our customer support team is fully versed in all elements of pad printing. Our goal is to find the right solution for you.

Ink

Printing ink is arguably the most important component of the printing process. A wide variety of ink series are available and choosing the correct one is critical for adhesion. Each printing ink series is developed for particular materials such as glass, metals, plastics, and more.

Printing ink is available in a wide variety of colors. Standard colors such as black and white are always available. Looking for more than just standard colors? Most inks are available as a Mixing Series to allow for custom color matching Pantone numbers are also a possibility.

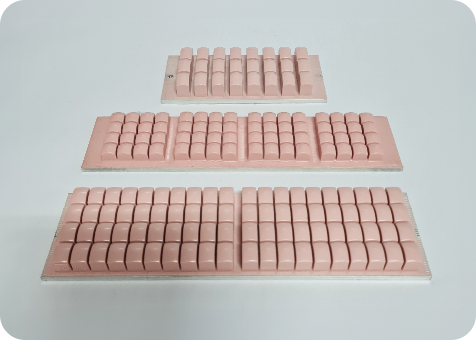

Pad

A printing pad is the ink transfer mechanism in a pad printing machine. The pad compresses onto the ink-filled etch to “pick-up” the image. The pad then slides over the part and once again compresses to apply the image. Pads are available in a variety of shapes and sizes. The size and shape of a pad is dependent upon the application and the artwork. Common pads are round and rectangular. There are, however, specialty pads with unique shapes made for specific applications.

Plate

A printing plate, also known as a cliché, holds the image to be printed. The plate is etched with the image. To ensure your plate is etched properly for printing.